Page 11 - Basic Principles Of Grooved Mechanical Joints

P. 11

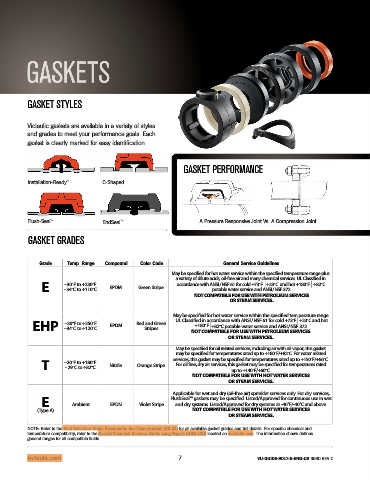

GASKETS

GASKET STYLES

Victaulic gaskets are available in a variety of styles

and grades to meet your performance goals. Each

gasket is clearly marked for easy identification.

GASKET PERFORMANCE

Installation-Ready ™ C-Shaped

Flush-Seal ™ EndSeal ™ A Pressure Responsive Joint Vs. A Compression Joint

GASKET GRADES

Grade Temp. Range Compound Color Code General Service Guidelines

May be specified for hot water service within the specified temperature range plus

a variety of dilute acids, oil-free air and many chemical services. UL Classified in

E –30°F to +230°F EPDM Green Stripe accordance with ANSI / NSF 61 for cold +73°F | +23°C and hot +180°F | +82°C

potable water service and ANSI / NSF 372.

–34°C to +110°C

NOT COMPATIBLE FOR USE WITH PETROLEUM SERVICES

OR STEAM SERVICES.

May be specified for hot water service within the specified temperature range.

EHP –30°F to +250°F EPDM Red and Green UL Classified in accordance with ANSI / NSF 61 for cold +73°F | +23°C and hot

+180°F | +82°C potable water service and ANSI / NSF 372.

Stripes

–34°C to +120°C

NOT COMPATIBLE FOR USE WITH PETROLEUM SERVICES

OR STEAM SERVICES.

May be specified for oil related services, including air with oil vapor, this gasket

may be specified for temperatures rated up to +180°F/+82°C. For water related

T –20°F to +180°F Nitrile Orange Stripe services, this gasket may be specified for temperatures rated up to +150°F/+66°C.

For oil free, dry air services, this gasket may be specified for temperatures rated

–29°C to +82°C

up to +140°F/+60°C.

NOT COMPATIBLE FOR USE WITH HOT WATER SERVICES

OR STEAM SERVICES.

Applicable for wet and dry (oil-free air) sprinkler services only. For dry services,

FlushSeal™ gaskets may be specified. Listed/Approved for continuous use in wet

E Ambient EPDM Violet Stripe and dry systems. Listed/Approved for dry systems at -40˚F/-40˚C and above.

(Type A) NOT COMPATIBLE FOR USE WITH HOT WATER SERVICES

OR STEAM SERVICES.

NOTE: Refer to the Seal Selection Guide Elastomeric Seal Construction (05.01) for all available gasket grades and full details. For specific chemical and

temperature compatibility, refer to the Gasket Chemical Services Guide Long Report (GSG-100) located on victaulic.com. The information shown defines

general ranges for all compatible fluids.

victaulic.com 7 VU-GUIDE-9017-E-ENG-US 9590 REV C